Prime Steel stands as a prominent manufacturer specializing in the production of copper-nickel 70/30 flanges. Our expertise in metallurgical engineering ensures that each flange meets stringent industry standards, offering superior corrosion resistance and durability, especially in marine and offshore environments. Our commitment to excellence extends to providing customized solutions tailored to meet the specific needs of clients, backed by comprehensive quality control measures to ensure consistent performance. With Our cupro-nickel 70/30 flanges, customers can trust in enduring quality and precision engineering for their critical piping systems.

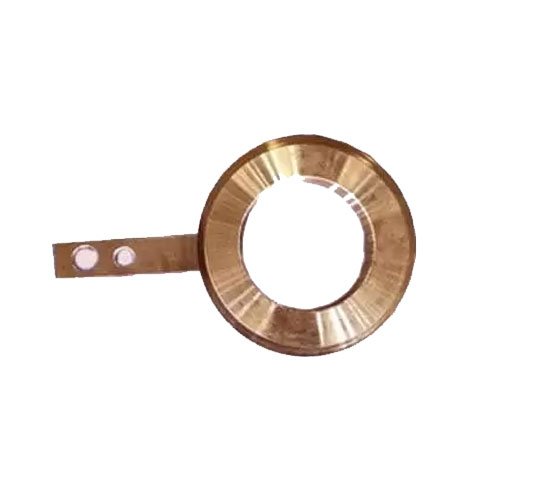

Type: Flanged Pipe Fittings

Material: Copper Nickel

ASTM: ASTM B122

Grade: 70/30

UNS: UNS C71500

WNR: 2.0882

ASTM B122 / ASME SB122 Cupro Nickel 70/30

15mm ( 1/2" NPS ) up to 600mm ( 24" NPS ), For 2500# in sizes from NPS 1/2 to NPS 12

FF—Flat Face, RF—Raised Face, FM—Female Face, M—Male Face, T—Tongue Face, G—Groove Face, RJ—Ring Joint.

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64.

Chemical Processing, Oil and Gas Industry, Petrochemical Industry

Copper Nickel 70/30 Flanges are integral components in piping systems, crafted from an alloy containing 70% copper and 30% nickel, with small additions of other elements. This alloy, known for its exceptional resistance to corrosion, particularly in marine environments, makes these flanges highly sought after across various industries.

Copper Nickel 70/30 alloy offers excellent mechanical properties alongside its corrosion resistance, making it suitable for a wide range of applications, including shipbuilding, offshore platforms, desalination plants, and chemical processing facilities. These Cu-Ni 70/30 Flanges are available in various types, including weld neck, slip-on, socket weld, and threaded flanges, catering to diverse piping requirements.

Check ANSI/ASME B16.5, B 16.47 Series A & B, B16.48 Flange Dimensions Download

| STANDARD | UNS | WERKSTOFF NR. |

|---|---|---|

| Cupro Nickel 90/10 | C71500 | 2.0882 |

| Grade | Mn | Cu | Pb | Zn | Ni | Fe |

|---|---|---|---|---|---|---|

| Cu-Ni 70-30 | 1 max | 65.0 min | .05 max | 1 max | 29-33 | 0.4-1.0 |

| Element | Density | Tensile Strength | Melting Point | Elongation | Yield Strength (0.2%Offset) |

|---|---|---|---|---|---|

| Copper Nickel 70-30 | 0.323 lb/in3 at 68 F | 50000 psi | 2260 F | 30 % | 20000 psi |